DC Affordable Living Competition: Materials

This is the fourth in our series of posts about the 2015 DC Affordable Living Design Competition. CallisonRTKL is working on a design for 10-15 single-family affordable townhomes in the Deanwood neighborhood of northeast Washington, DC that meets the mandates of the Living Building Challenge (LBC), widely recognized as the world’s most ambitious building performance standard. The LBC uses the metaphor of a flower deeply rooted in its place to give shape to its holistic design criteria. It is structured around seven performance categories, or “petals,” representing aspects of sustainable design: Place, Water, Energy, Health and Happiness, Materials, Equity and Beauty. This blog addresses the Materials petal.

Although Net Zero Energy and Water are often the big topics of discussion around sustainable buildings, material selection and health are increasingly pushed to the forefront of conversation. LEED has dealt with material selection for years, but the Living Building Challenge pushes the envelope further by demanding material transparency and health.

The movement toward material transparency is in its early stages, and the market needs significant transformation to encourage compliance. That said, the Materials petal may be one of the hardest to achieve.

The Red List

One of the requirements of the Materials petal is that no material or product used in the building can contain any chemicals identified on the “Red List,” a compilation of 22 chemicals proven to be detrimental to human and environmental health. Some of these you may be quite familiar with—such as PVC, asbestos, and lead—but others, like chlorobenzenes and perfluorinated compounds, don’t often come up in everyday conversation.

Finding building products without these components is no easy task and requires cooperation from and effort by designers, manufacturers and the full supply chain. Many manufacturers only control the final assembly of their product and are unable to confirm that no Red List chemicals are involved in the processing of their product throughout the entire life cycle. A great deal of time and effort is required by both project teams attempting this petal and product manufacturers’ representatives to confirm that every product specified is guaranteed to be free of red list chemicals.

While avoiding Red List substances can have a clear positive influence on occupant health, there are concerns about some of the materials used to replace them. In a race to remove banned substances, there simply has not been adequate research to determine whether or not replacement chemicals may have just as much, or even more, harmful potential.

Shopping simple, shopping local

Our strategy for the Deanwood competition is to “shop the perimeter of the grocery store” for materials, as one of our recent charrette presenters, Rus Perry, described to us. By selecting simpler “non-processed” materials in the first place, it is easier to determine the entire chemical composition and less likely that they will contain Red-Listed chemicals. Just as we are told to not eat foods that contain things we can’t pronounce, we aim to simplify building material selection.

Not only are we looking for “non-processed” materials, but we are looking for reused or salvaged local material to minimize our use of virgin resources. We follow these simple rules:

- Reuse material whenever possible

- Select “non-processed” local materials

- Stay away from plastics

Finally, we prioritize buying local. Once again, for the same reasons as we buy local for food, our buying power has the opportunity to support local businesses, stimulate the economy, and reduce the amount of energy and emissions caused by shipping and transportation.

Education and Raising Awareness

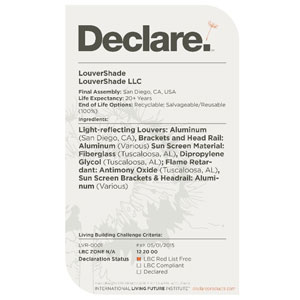

Perhaps the greatest power the Materials petal wields is in the push for product transparency and increased education. The International Living Future Institute began the Declare Program, described as a “nutrition label” for building products, to create a consistent and public way for manufacturers to disclose the product content. While the database is still quite small, it is a great step toward material transparency and improving the feasibility of Living Building Challenge projects.

There are several other movements within the industry that are helping to improve product health and sustainability. The Health Product Declaration Collaborative created a standard disclosure method for potentially harmful chemicals in products. HPD and Declare are working together to streamline the required processes for materials transparency.

As part of this competition, our team sent letters to several manufacturers, encouraging them to pursue Declare labels or Health Product Declarations for their products. While there is still much work and research to be done, the progress that the architecture and design industry has made in the past few years regarding material health shows how much impact can be made when firms and manufacturers work together toward a common goal.

Cover image via Flickr (NatalieMaynor)